Flatness restoration and groove grinding equipment for grinding wheels

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Why is it necessary to restore the flatness of the grinding wheel?

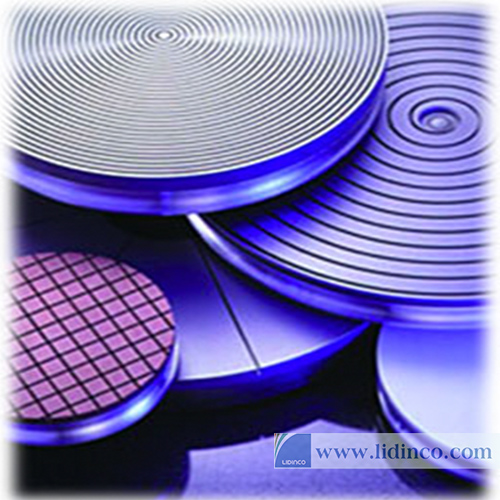

The grinding wheel, also known as the polishing plate, is the part of the lapping machine, which plays the most important role in the polishing process because it is in direct contact with the molds to be polished. During continuous grinding processes, the surface of the grinding wheel may become convex or concave depending on the position of the specimen.

If the surface of the grinding wheel is deformed, the flatness does not reach the desired level, the flat grinding process will not be effective, leading to damage to the molds, the sample to be polished. In this case, there are two ways to restore the efficiency of the process: to replace the wheel or to restore the flatness of the wheel in use. Of course, the flatness restoration method will be used because it is much more cost-effective than replacing the wheel.

Introduction of flatness restoration and groove grinding equipment for grinding wheels

Panel flatness can be restored by two methods: manual or automatic

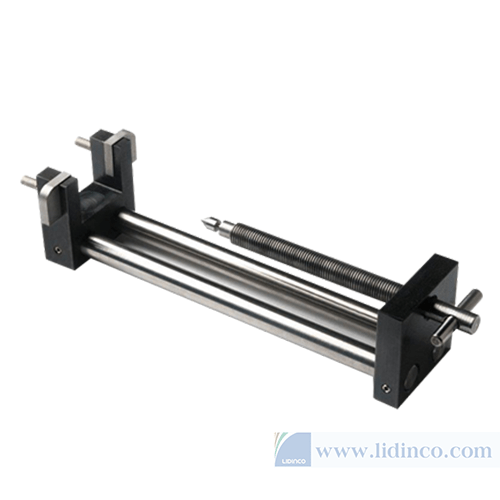

- Manually restore flatness: Use the flatness gauge to determine if the grinding wheel surface is convex or concave. Then, apply weights to the convex or concave areas to restore flatness. The disadvantage of manual process is that it is time consuming and requires high skill of the operator

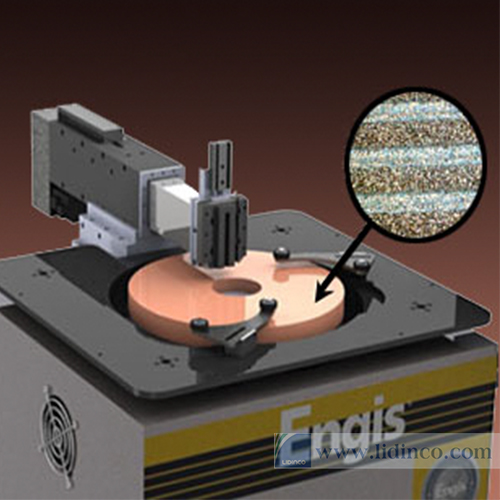

- Automated Flatness Restoration: Use Engis' FastLap flatness restorer to restore wheel flatness quickly and accurately. The device helps to mill the surface of the grinding wheel with flatness and high precision in the micron range. The process of restoring the surface of the flat grinding plate will include two stages

- Stage 1: Turn the surface according to the preset size

- Stage 2: Grinding grooves on the surface to increase the efficiency of grinding and polishing

Machine flat restoration with greater accuracy and less time is a top choice for jobs that require continuous progress. The ability to precisely control the surface is also an outstanding advantage of this device

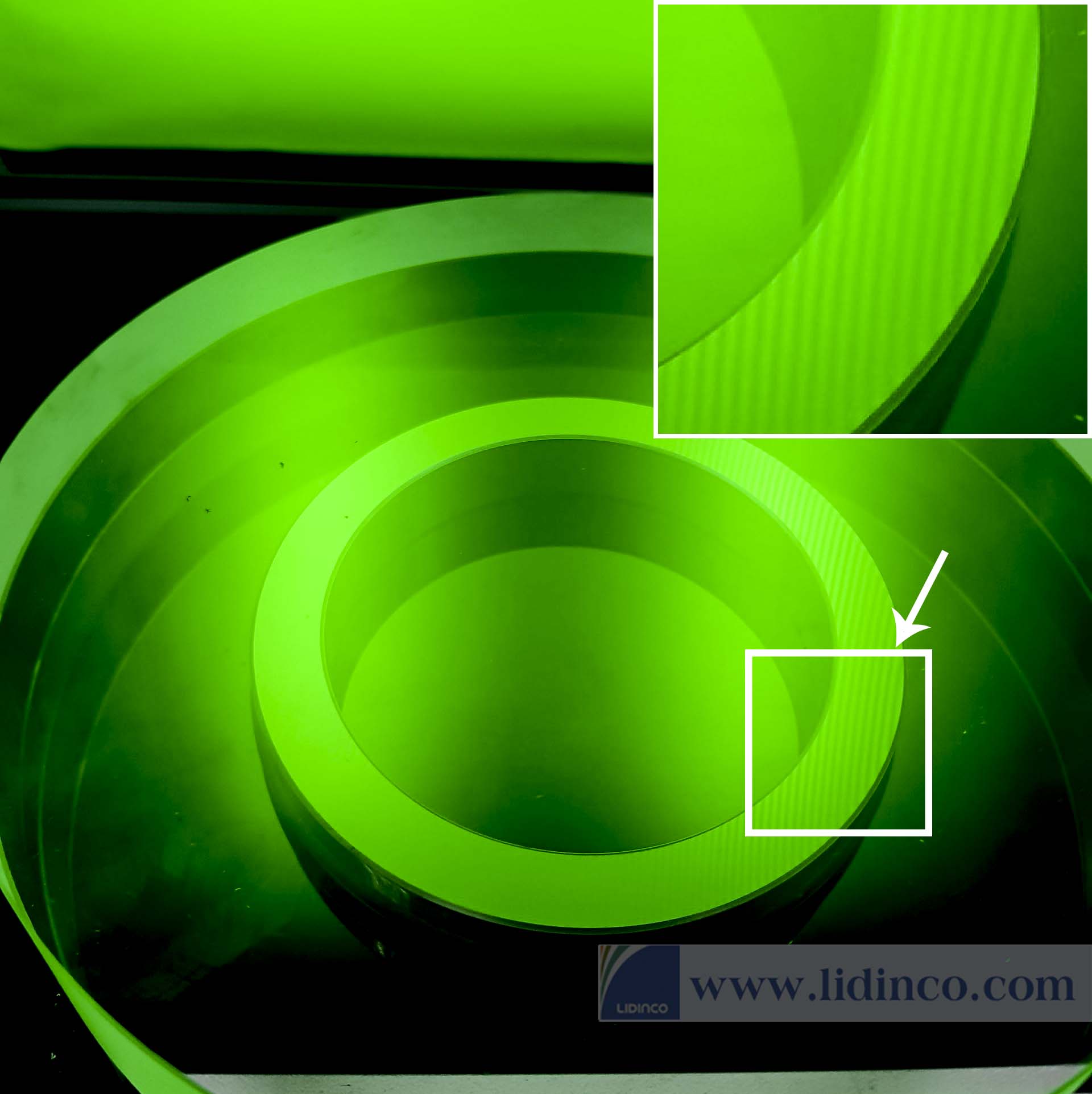

Effect of grooves on grinding wheel surface on grinding efficiency

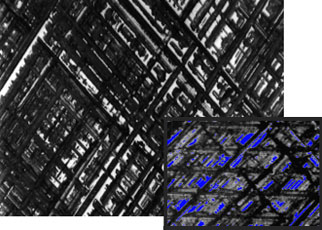

Controlling the grooves on the surface of the grinding wheel (macrostructure) and the microstructure on the groove also greatly affects the grinding speed and the surface finish of the mold. The more even the grooves on the surface, the more efficient the lapping and polishing process will be

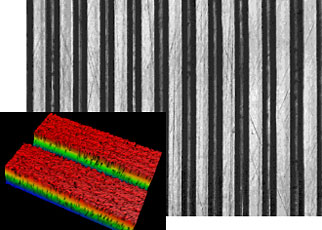

Macro structure: Uniform grooves are made by Engis groove grinding equipment for high efficiency

Microstructure: Uneven, causing diamonds to not be evenly distributed on the surface of the grinding plate

Engis with many years of experience in the field of flat grinding, polishing molds. Engis materials and machines are always appreciated and are the first choice of large factories around the world. To purchase Engis equipment as well as equipment selection advice, contact Lidinco for the lowest support.

Explore more:

Accessories

Please login to write review!