Bánh mài cho máy mài phẳng USA – Tấm đánh bóng phẳng

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

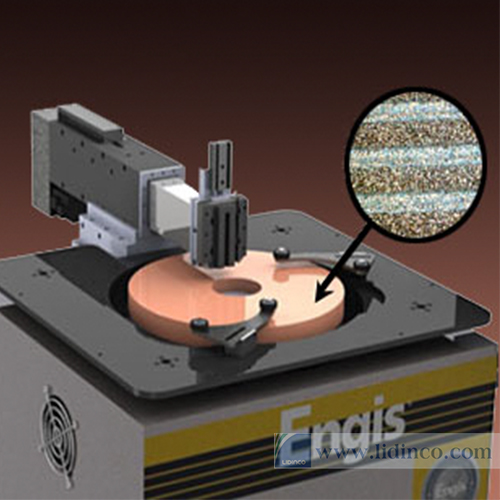

The grinding wheel used for lapping machine is one of the most important factors affecting the efficiency of the lapping process. However, in the lapping process there are many materials that can be used. These materials have different hardness, softness, different structural characteristics, different surface finishing requirements. As a result, Engis offers you flat polishing plates with diamond retention, different surface removal speeds suitable for a wide range of materials making it easy for you to choose for your application.

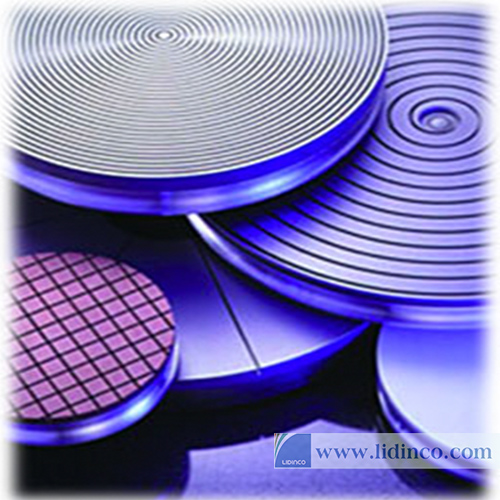

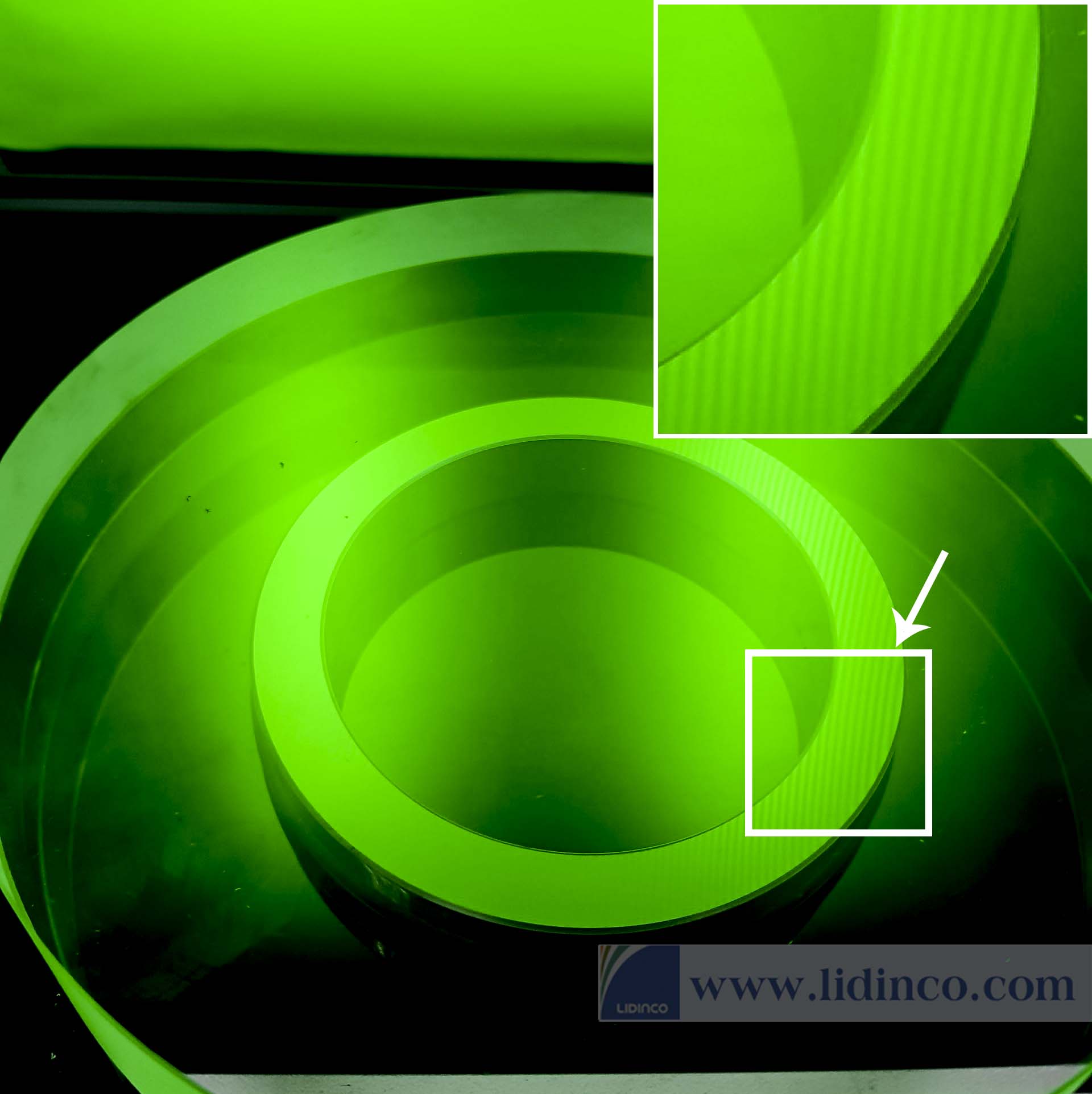

Engis grinding wheels are specially designed with a combination of synthetic materials and natural metals. The surface of this grinding plate has structures such as: rough, square groove, concentric, radial, spiral.. giving you many choices, suitable for optimizing lapping process according to the characteristics of the die type. need polishing

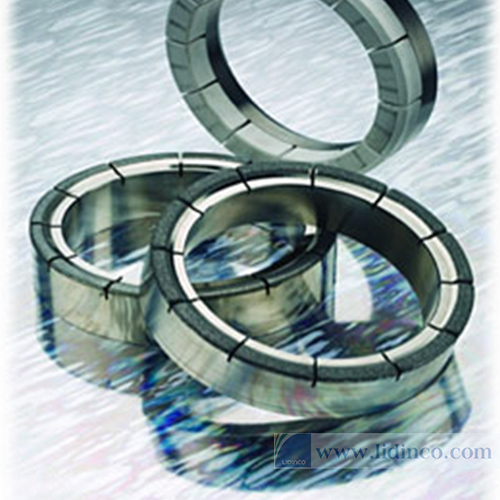

– Special synthetic materials combined with natural metals

The special structural composition is created from a unique blend of metal, ceramic, bonded by a plastic structure. These flat polishing plates will help to distribute the diamond particles more evenly, easy to control the polishing performance. In addition, these grinding wheels also help shorten the grinding and polishing process (lapping & polishing) into a single step, saving maximum time.

– Homogeneous finishing of different materials

Hyprez panels used in combination with diamond powder are ideal for finishing mold surfaces for uniform flatness. Contact Lidinco for advice on consumable materials such as: diamond powder, diamond polishing solution, abrasive oil ... in combination with grinding wheels to achieve the highest efficiency.

– Diameter of flat grinding plates

We have flat grinding plates of different sizes available for a wide range of lapping machines from other brands, not just Engis equipment. Available grinding plate diameters: 6″, 9″, 12", 15", 16", 18", 24", 28", 36", 42" and 48". Square, spiral, concentric, radial.. can be customized according to the above dimensions

** Note: Flat grinding plate after using for some time may lead to surface convex or concave. Making flat polishing will face many limitations and not high efficiency. Engis flatness gauge is required to determine the condition of the grinding wheel and restore the surface for best performance

Types of flat grinding plates, grinding wheels are being provided by Engis

Hyprez X08" grinding wheel

– Best surface removal (fast grinding speed)

– Composite iron plate ranks 2nd in hardness

– Offers excellent flatness, long service life, low need for surface restoration, provides delicate surface finishes

– Often used as an alternative to cast iron panels

– Good use with most materials, especially ceramic metals

Hyprez TX-10A . grinding wheel

– Average surface removal capacity

- Made of synthetic tin

– Provides a surface finish prior to polishing

– Works well with diamond powders and diamond polishing solutions for a more perfect surface

– Long service life, low need for surface restoration, provides delicate surface finishes

Backplate for Hyprez Tin-Antimony polishing machine

– Low surface rejection

– Typical plate for head manufacturing industry (kiss lab process)

– Used for rough polishing of hard metal materials, SiC, GaN

- Resistant to high temperatures during polishing

Prevents viscosity change of lubricants during continuous running

Hyprez HY grinding wheel with spiral pattern

High surface removal capacity is used in roughing operations to optimize grinding time to the required polishing point on the specimen.

– Often used as an alternative to cast iron panels

– Good adaptability to most materials, especially metals and ceramics

Usually used with rough to medium diamond powders

Hyprez HY Copper Flat Grinding Plate

– Average surface removal capacity

– The most widely used of all flat grinding plates

– Excellent backing plate for two stages of rough polishing and fine polishing of the mold surface

Suitable for most solid materials such as metal, ceramic, glass, carbon, plastic...

- Good for use with diamond particles < 14 micron

– Minimize surface cracking or chipping

Hyprez HY flat grinding plate

– Moderate abrasion resistance

Commonly used for flat grinding and polishing of ceramic parts and stain-sensitive materials

– Used in applications where dust contamination needs to be kept to a minimum

– More affordable and easier to replace. Can replace natural ceramic tiles

- Very flexible usability. Can be used for polishing from coarse to fine

Accessories

Please login to write review!