MetPrep 3 Grinder/Polisher with Powerhead for Hot/Glove-Box

MetPrep 3 Grinder/Polisher with Powerhead for Hot/Glove-Box

-

Number Of Workspace:

-

Shaft Rotation:

- Available: Please contact

- There are currently no promotions for this product

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

MetPrep 3 Grinder/Polisher with Powerhead for Hot/Glove-Box

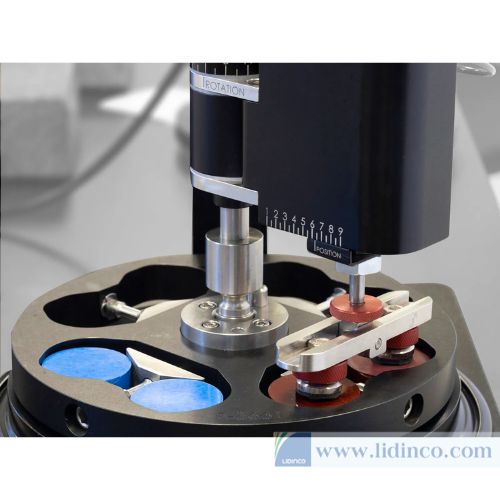

The MetPrep3™/PH-3™ Glove Box grinder/polisher for hot/glove-box environments is a powerful system for semiautomatic operation, ideal for low to high volume sample preparation requirements. It is designed to withstand various glove box environments (i.e., alpha-radiation inert) and has an overall reduced size to fit through most glove box portholes. Critical components of the machine have been removed to an external (remote) control box. Removable cover/side plates allow easy access for serviceability.

Intuitive menu navigation with user-friendly touchpad interface and backlit LCD make them easy to use and program. The microprocessor-based system allows up to 25 programmable steps, including parameters for platen speed, comp/contra rotation (sample holder/platen), cycle time, fluid selection, sample force (LbF or N), sample rotation speed, water rinse and force reduction (on/off, %)

Either aluminum or magnetic platens may be used with any plain/adhesive backed or magnetic system disc.

MetPrep 3

| Touch-pad switches control all functions | External control box with 8' shielded cable allows remote operation | |

| Removable side plates allow easy access for serviceability | Reduced size fits through 14" diameter port-hole (some assembly required "in box") | |

| Programmable up to 25 polishing steps, including parameters for platen speed, comp/contrarotation (sample holder/platen), cycle time, fluid selection, sample force (LbF or N), sample rotation speed, water rinse and force reduction (On/Off, %) | Quick-change platen design, anodized to resist wear and corrosion | |

| Variable platen speed: 50-400 RPM (10 RPM increments) | Clockwise/counterclockwise platen rotation | |

| ¼ HP (190 W) motor with durable reduction gearbox provides constant high-torque output | Variable platen jog speed: 50-400 RPM (10 RPM increments) | |

| Backlit 4-line LCD | Variable cycle time: 0-60 minutes (15 second increments) | |

| Stable aluminum/stainless steel construction | Corrosion/impact resistant cover | |

| Emergency shut-off switch |

PH-3 Power Head

| Central and Individual sample force functionality | Soft-start and force reduction control | |

| Unique tilt-up feature allows easy access to platen and holder | Simple push-button attachment and removal of holders | |

| Quick-lock allows sample holder positioning across entire platen surface | 1/8 HP (95 W) motor with durable reduction gearbox provides constant high-torque output | |

| Variable rotation speed: 10-150 RPM (10 RPM increments) | Complementary and contra rotation | |

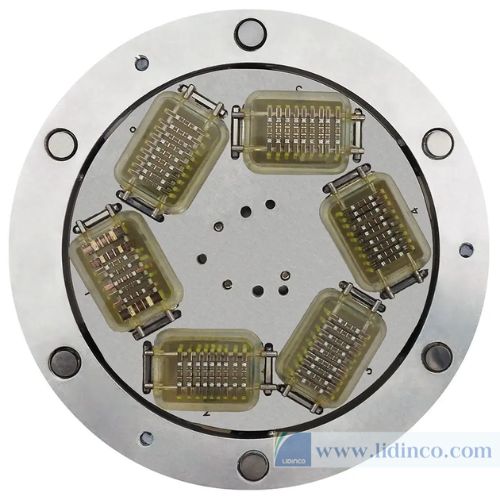

| Central force sample preparation of up to 6 samples | Quick-change sample holders: teardrop or dual-cavity, 25 - 40 mm capacity, #5-33XX series | |

| Pneumatically applied sample force: 5-50 lb. in 1 lb. increments (22-219 N in ~5 N increments) | Dimensions: 13" W x 19.5" D x 22" H (330 x 495 x 559 mm) | |

| Weight: 120 lb. (54 kg) | Shipping Weight: 180 lb. (82 kg) | |

| (1) years warranty | Lead Time: 12 - 16 weeks | |

| Designed & manufactured by Allied in the USA |

Accessories

Splash Ring and 18' Cable with Standard Connectors

-

Number Of Workspace:

-

Shaft Rotation:

The MetPrep 1x™ precision grinding/polishing machine

Please login to write review!