OptiPrep Polishing System

-

Number Of Workspace:

-

Shaft Rotation:

- Available: Please contact

- There are currently no promotions for this product

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

The OptiPrep™ System is designed for production polishing of a wide variety of optical components including: Ferrules, Connectors, Waveguides, Silicon V-groove, Optical Chips, Capillary/Glass Lenses, Fiber Bundles, Ribbon Fiber and Bare Fiber

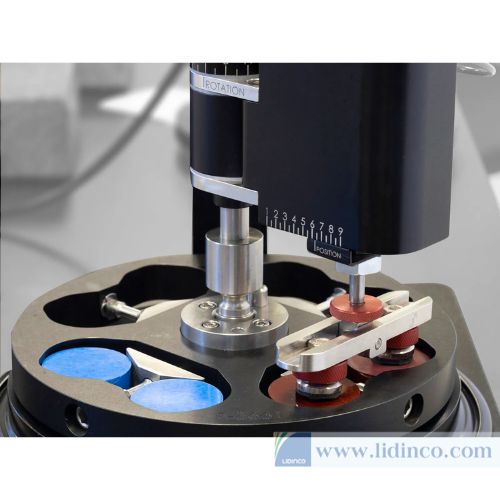

Optical polishing applications rely on specific geometry. The OptiPrep™ features a fixed cam-lock interface reference that is parallel to the plane of the platen. Desired sample angles are obtained based on geometric orientation built into the fixture.

Z-positioning/indexing is displayed on the digital indicator with 1-micron resolution, and can be pre-set for unattended operation. Variable speed rotation/limit rotation and oscillation with variable sweep maximize use of the entire abrasive surface.

Adjustable load control expands its capability to handle a range of small (delicate) to large samples.

Applications where the OptiPrep™ is used often require custom fixtures. Please contact Allied for assistance with a current fixture or to design and manufacture a fixture for a complete solution

Features

Grinder/Polisher

| Variable platen speed: 5-350 RPM, in 5 RPM increments | 7″ LCD touchscreen with keypad entry to control all functions | |

| ¼ HP (190 W) DC motor with durable reduction gearbox provides constant high-torque output | Digital timer and tachometer | |

| Integrated controls for operation of the OptiPrep™ Positioning Device | Clockwise/counterclockwise platen rotation | |

| Quick-change platen design, anodized to resist wear and corrosion | Corrosion/impact resistant cover | |

| Bowl flush to prevent debris build-up | Electronic coolant control with adjustable valve |

OptiPrep Positioning Device

| Front digital indicator displays real-time material removal/sample advancement | Rear digital indicator displays vertical positioning (static) with zeroing function, 1 micron resolution | |

| Precision spindle design indexes sample perpendicular to the platen, and can rotate simultaneously | Automatic sample oscillation, adjustable sweep with 6 speeds | |

| Full or limited automatic sample rotation with 8 speeds | Cam-locking system eliminates the need for tools and allows for exact repositioning of fixtures | |

| Dimensions: 15″ W x 26″ D x 20″ H (381 x 660 x 508 mm) | Weight: 95 lb. (43 kg) | |

| Shipping Dimensions: 33″ W x 31″ D x 15″ H (838 x 787 x 381 mm) | Shipping Weight: 125 lb. (57 kg) | |

| Two (2) year warranty | CE Compliant | |

| Designed & manufactured by Allied in the USA |

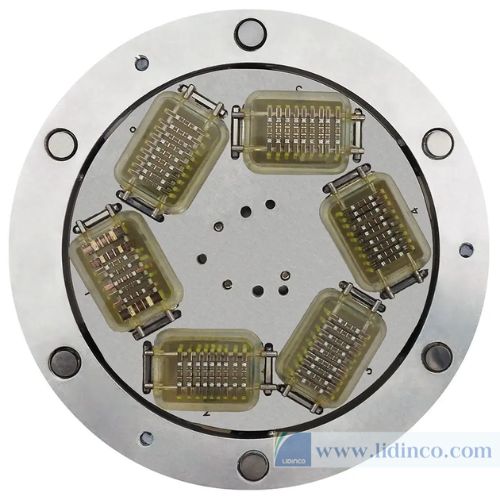

Accessories

- 12-Position V-Block Fiber Optic Capillary/Ferrule Holder, 0º

- 6-Position Bare Fiber Polishing Fixture, 0º (125µ fiber diameter)

- 6-Position Bare Fiber (in ferrule) Polishing Fixture, 9º (125µ fiber diameter)

- 4-Position Bare Fiber Polishing Fixture, 12° Angle

- Waveguide Fixture, 0° with reference edge, reversing (requires use of 15-1005)

- Waveguide Fixture, 10° with reference edge, reversing (requires use of 15-1005)

- Waveguide Fixture, 4° with reference edge, reversing (requires use of 15-1005)

- Waveguide Fixture, 6° with reference edge, reversing (requires use of 15-1005)

- Waveguide Fixture, 8° with reference edge, reversing (requires use of 15-1005)

-

Number Of Workspace:

-

Shaft Rotation:

The MetPrep 1x™ precision grinding/polishing machine

Please login to write review!