X-Prep Precision Milling/Polishing System

X-Prep Precision Milling/Polishing System

- Đang có sẵn: Vui lòng liên hệ

- Tạm thời chưa có khuyến mãi cho sản phẩm này

Hotline: 0906.988.447

Liên hệ: Hồ Chí Minh

- Điện thoại: (028).3977.8269

- Email: sales@lidinco.com

- Địa chỉ: 487 Cộng Hòa, Phường Tân Bình, TP. Hồ Chí Minh, Việt Nam

Liên hệ: Bắc Ninh, Hà Nội

- Điện thoại: (0222).730.0180

- Email: bn@lidinco.com

- Địa chỉ: 184 Bình Than, Phường Võ Cường, Bắc Ninh, Việt Nam

-

Tư vấn kĩ thuật

Miễn phí

Tư vấn kĩ thuật

Miễn phí

-

Miễn phí vận chuyển

Đơn hàng trên 3 triệu

Miễn phí vận chuyển

Đơn hàng trên 3 triệu

Dữ liệu đang được cập nhật

Máy mài, phay, đánh bóng độ chính xác cao từ Allied Hight Tech dành cho chuyên ngành sản xuất. Sản phẩm hỗ trợ kỹ thuật cho công tác kiểm tra mà các cách kiểm tra bằng vật lý, điện khác gặp thất bại.

Màn hình độ phân giải cao.

Sản phẩm đi kèm loạt các phụ kiện khác phục vụ lấy mẫu

X-Prep Precision Milling/Polishing System

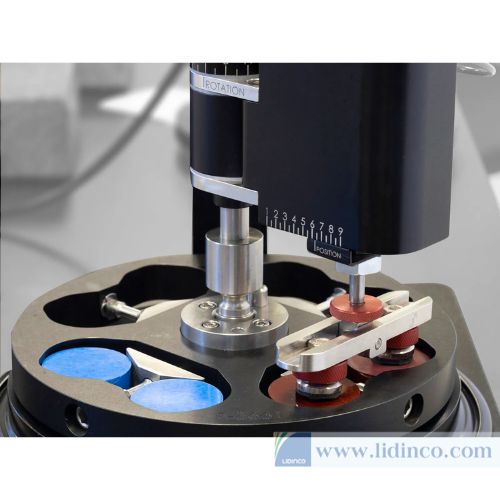

The X-Prep® is a specialized 5-axis CNC-based milling/grinding/polishing machine designed to support electrical and physical failure analysis techniques and other applications requiring high precision sample preparation.

It features a wizard-based, user-friendly, intuitive interface that guides the operator through a screen sequence. As each screen appears, instruction is provided to the operator, ensuring every parameter and function is defined before operation. Help buttons on each screen provide access to additional explanation and instruction.

A high-definition (720p) color camera projects a magnified, razor-sharp image of the sample onto the touch screen to help the operator define the X/Y milling/grinding/polishing boundary.

Automatic tilt adjustment levels the sample plane parallel to the X/Y plane of the cutting tool. Unevenly mounted or tilted samples can easily be leveled using this functionality.

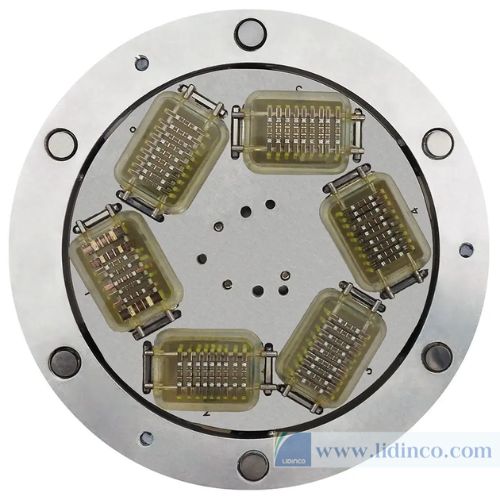

A variety of fixtures and accessories are available to accommodate various sample types and sizes.

| Easy-to-use, wizard-based workflow guides the operator through system setup to define: X/Y/Z milling position; X/Y milling rate; Z-force; Z-increment; milling pattern/tool path; tool overlap and more | Three (3) modes of control: Position (Milling/Grinding); Position Force (Grinding/Polishing); Floating Force (Polishing) | |

| 3D (X, Y and Z) convex and concave machining capability | Requires no G-coding or programming knowledge | |

| Motorized tilt stage provides automatic, closed-loop 3-point leveling of the sample and custom leveling, 0.5 micron resolution | Live video navigation to define X/Y milling region | |

| Closed-loop Z-axis positioning, 0.1 micron resolution, 1 micron accuracy | Closed-loop X/Y-axis positioning, 1 micron resolution | |

| 12" color LCD, touch-screen graphic user interface | Closed-loop Z-axis force control, 0.5 to 10 N | |

| Universal tool collet uses 3 mm x 1.5" (38 mm) length tools (0.25 mm - 12 mm grinding/polishing tip) | 100 x 100 mm milling region | |

| Weight: 185 lb. (84 kg) | Dimensions: 21" W x 27" D x 25" H (533 x 686 x 622 mm) | |

| Designed & manufactured by Allied in the USA | Two (1) year warranty |

- Fixture for X-Prep®, 2" x 2" Capacity

- Borosilicate Glass Inserts, 2" x 2" x 1/8" Thick (Pk/20)

- Aluminum Inserts, 2" x 2" x 1/8" Thick (Pk/10)

- Fixture for X-Prep®, 3" x 3" Capacity

- Borosilicate Glass Inserts, 3" x 3" x 1/8" Thick (Pk/10)

- Fixture for X-Prep®, 4" x 4" Capacity

- Borosilicate Glass Inserts, 4" x 4" x 1/8" Thick (Pk/10)

- Fixture for X-Prep®, 4" x 6" Capacity

- Borosilicate Glass Inserts, 4" x 6" x 1/8" Thick (Pk/10)

- Fixture Clamp Set, X-Prep® (Pk/4)

- Tool Dressing System Module for X-Prep®

- Dust Extraction System for X-Prep®, 115 V AC

- Dust Extraction System for X-Prep®, 230 V AC

- Ruby Tipped Leveling Probe

- Ruby Tipped Stylus, 10 mm L - 1 mm Ø ball, M3 Thd.

- X-Prep® Assortment Starter Tool/Consumables Kit

Phụ kiện

Vui lòng đăng nhập để viết đánh giá!