MetPrep 4 Grinder/Polisher with Powerhead

MetPrep 4 Grinder/Polisher with Powerhead

-

Number Of Workspace:

-

Shaft Rotation:

-

Diameter Plate:

- Available: Please contact

- There are currently no promotions for this product

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

The MetPrep 4™ grinding and polishing machines, with the PH™ line of power heads, are powerful systems for semiautomatic operation, ideal for low to high volume sample preparation requirements. A wide variety of combinations provides ideal solutions that accommodate any lab, application, or material.

Intuitive menu navigation with a user-friendly touchpad interface and backlit LCD make them easy to use and program. The microprocessor based system allows up to 25 programmable steps, including parameters for platen speed, comp/contra rotation (sample holder/platen), cycle time, fluid selection, sample force (LbF or N), sample rotation speed, water rinse, and force reduction (on/off, %).

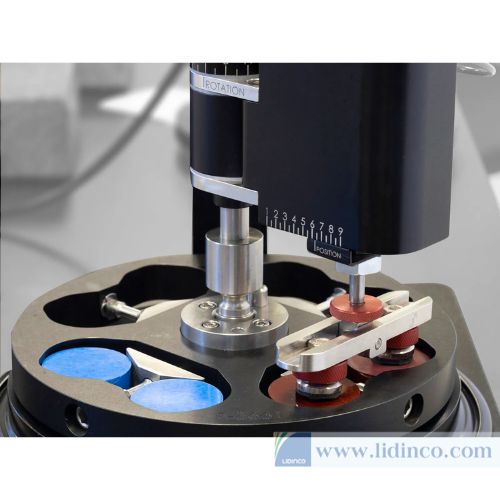

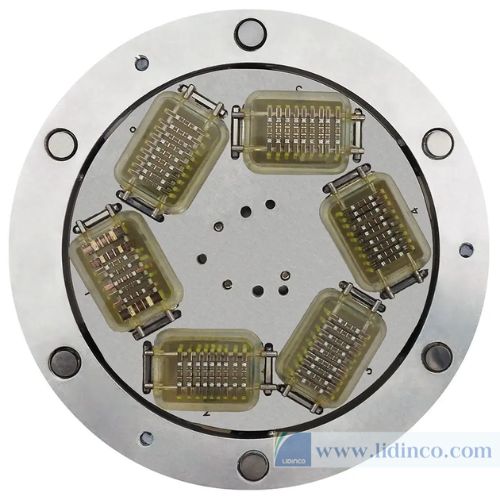

The PH-4™/PH-6™ power heads offer maximum versatility for low to high volume semi-automatic sample preparation, using either central or individual sample force modes. The pneumatic-electric system provides controlled sample force and allows up to 12 samples to be prepared simultaneously, depending on power head, mount diameter, and holder size. The unique tilt-up design allows easy, unhindered access to the sample holder and platen, and eliminates the need to reposition the head during the preparation procedure.

Either standard or magnetic platens may be used with any plain/adhesive-backed or magnetic system disc.

Features

MetPrep 4

| Programmable up to 25 grinding/polishing steps, including parameters for force mode, platen speed, comp/contra rotation (sample holder/platen), cycle time, fluid selection, sample force (LbF or N), sample rotation speed, water rinse and force reduction (on/off, %) | Sturdy RIM, aluminum and stainless steel construction with low-profile design | |

| Variable cycle time: 0-120 minutes (15 second increments) | Molded one-piece corrosion resistant cover | |

| Powerful 1.5 HP (1100 W) motor with constant high torque output | Quick-change platen design, anodized to resist wear and corrosion | |

| Electronic coolant control with adjustable flow control valve | Touchpad switches control all functions | |

| Adjustable, pivoting coolant nozzle allows quick and easy sample/bowl cleaning | Variable platen and jog speed: 50-400 RPM (10 RPM increments) | |

| Seamless integration with optional AD-5™ Fluid Dispenser for automatic operation | Overflow diversion to protect internal components | |

| CE compliant for EU | Emergency shut-off switch | |

| Two (2) year warranty | Designed & manufactured by Allied in the USA |

PH-4 & PH-6 Power Heads

| Central and Individual sample force functionality | Soft-start/stop force control | |

| Unique tilt-up feature for easy access to platen and holder | Simple push-button attachment and removal of sample holders | |

| Quick-lock system allows sample holder positioning across entire platen surface | Safety sensor that stops operation if power head is tilted up | |

| Variable rotation speed: 0-150 RPM (10 RPM increments) | 0.33 HP (246 W) motor with durable reduction gearbox provides constant high torque output | |

| Comp and contra rotation | Two (2) year warranty | |

| Designed & manufactured by Allied in the USA |

Accessories

Splash Ring and Platen Cover

-

Bandwidth:

-

Sampling Rate:

-

Waveform Length:

-

Channels:

Micsig TO1152 150MHz Tablet Oscilloscope

Please login to write review!