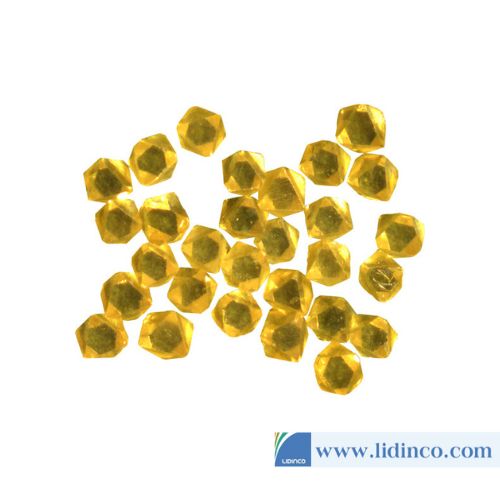

HYPREZ® Diamond and Non-Diamond Lapping Slurries

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

Engis has developed a complete range of diamond slurries, as well as complimentary micro-graded alumina and colloidal slurries, for every precision lapping application. Our slurries excel in the lapping of ceramics, metals, sapphire, silicon carbide, gallium nitride, and mechanical seals.

Our diamond slurries deliver to you a faster, greener and more cost effective process over lapping with conventional abrasives. In addition to the aggressive cutting ability of diamond, Engis’ formulations provide you with superior surface finishes, faster part clean up, greater efficiencies and significantly less waste to dispose of.

Engis Hyprez diamond slurry formulations are engineered to assure that the diamond particles are well dispersed, stay suspended and dispense freely. Our slurry chemists have tailored our formulations to optimize the physical characteristics of the slurry vehicle in order to deliver consistent and efficient results, taking full advantage of the diamond abrasive. To complement our standard range of oil, water based, or emulsion carriers, Engis can also custom engineer a slurry for even your most demanding applications utilizing particles as small as 50 nanometers. Our extensive R&D department and Process Development Lab ensure that our family of slurry products always stay ahead of the curve in terms of lapping efficiencies and part quality.

Engis is a diamond micronizer….this gives us 100% control over the Particle Size Distribution of the diamond abrasive used in our slurries. Thanks to the stringent controls we have over the PSD, we can eliminate stray coarse and fine particles providing you with a slurry formulation that cuts faster and finishes better than other products in the same nominal micron size. Read more about the precision of Engis Diamond Powder.

Oil Soluble

• Provides superior lap plate wetting and film protection for hard laps such as ceramic, cast iron, and series HY composite laps

Engis Corporation

Engis Corporation Engis HYPREZ® Family of Diamond and Non-Diamond Lapping Slurries

Engis HYPREZ® Family of Diamond and Non-Diamond Lapping Slurries

• Excellent on most metal and carbide parts with excellent cleanability

• Especially popular for finishing materials where a highly reflective finish is desired

• Workhorse oil soluble slurry: S1313

Water Soluble

• Used as an alternative to oil based slurries in applications sensitive to oil content

• Widely used in the processing of electronic and electro-optical components as well as single crystal semiconductor substrates, and magnetic read/write head

• Workhorse water soluble slurry: S4889

Emulsion

• Works well with Engis Hyprelube or W lubricant and is particularly suited for use with polishing cloths and pads

• Maintains dispersion of diamonds in the finer micron sizes without settling for long periods of time

• Re-disperses easily with shaking

• Workhorse emulsion slurry: S841

Permanent Suspension

• Some applications require oil and or water soluble slurries that do not need to be stirred during the process

• Suspensions exhibit excellent performance for a wide range of applications and are available in concentrate form, which can be diluted by the customer

• Workhorse suspension slurry: S4243

Colloidal Aluminas and Silicas

• Engis offers non-diamond abrasive slurries as well for your final polish operations as well as softer materials which do not require diamond.

We also offer a range of cleaners specifically formulated to be used with our lapping slurries and vehicles.

• CL10012 – is our environmentally friendly “green” cleaner, it can be used to clean your S1313 oil based slurry, S841 emulsion, or S10024 oil suspension slurries and is completely disposable

• 5772 – is a more effective cleaner but contains some petroleum based products – it can be used with the same three products

• 4615 – is a more mild cleaner and is designed to be used with S4889 water based slurry, and S4243 water suspension

Accessories

Please login to write review!