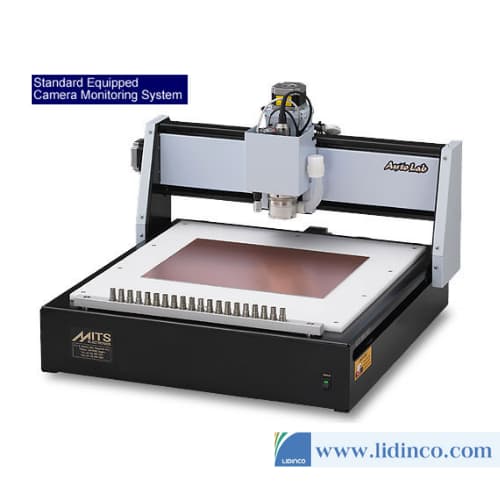

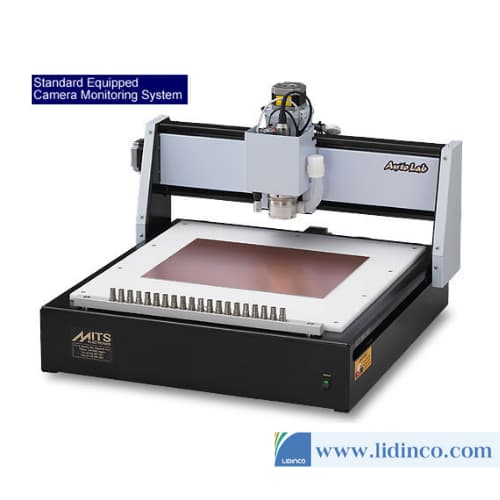

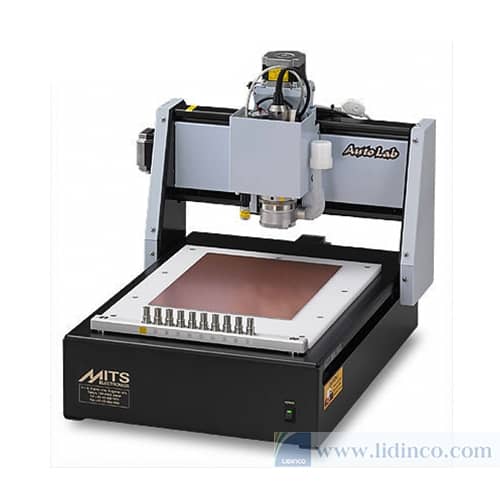

PCB Prototyping Mits Auto Lab 100

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Ward 15, Tan Binh Dist, HCM City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh City, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

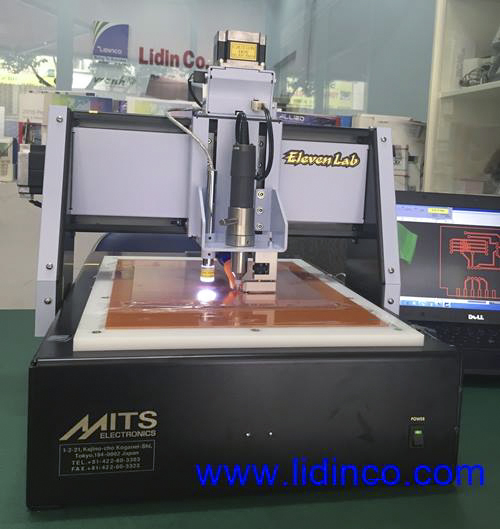

Auto Lab 100 model employs Auto-Tool-Change mechanism and achieves a low price, while its specification exceeds Eleven Auto. Up to 10 tools are available for automatic tool change. The standard spindle motor is made in Japan with high quality and less runout. Tool change employs the electrical function without using the air compressor.

- Spindle speed 100,000rpm

- 10 Auto Tool Change

- Standard Equipped

- Camera Monitoring System

- Cabinet (option)

Features:

Equipped Auto-Tool-Change and providing the superior cost performance:

Auto Lab replaces Eleven Auto. This model employs Auto-Tool-Change mechanism and achieves a low price, while its specification exceeds Eleven Auto. Up to 10 tools are available for automatic tool change.

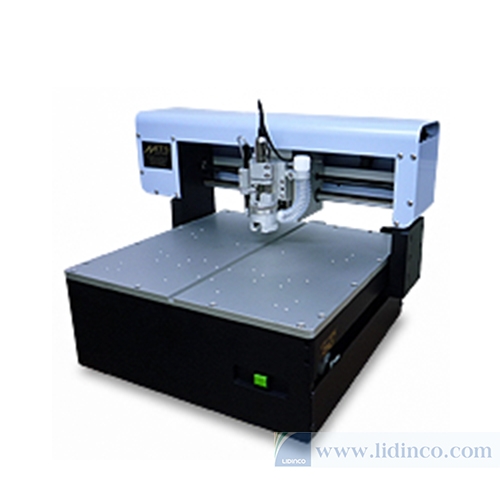

Cabinet (requires assembly) is available as an optional item:

Well designed and easy to perform maintenance.

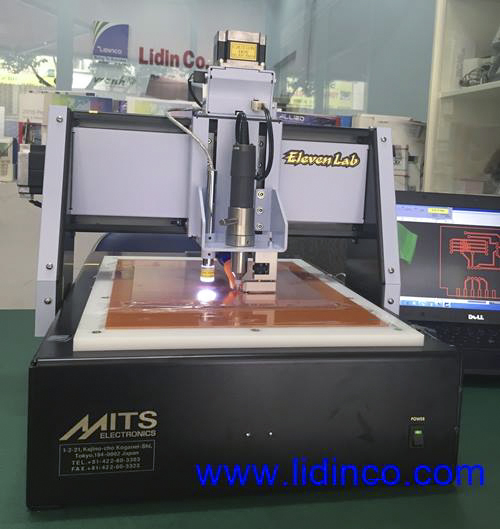

Standard camera monitoring system:

Magnify the surface of the board and display on a monitor. You can easily adjust the right position while viewing display.

(Maximum useful magnification depends on the size of the screen)

Optional equipment make it even easier to process:

Vacuum table: The vacuum table option employs the porous resin which holds tightly in the whole area

of the surface. This stabilizes the substrate tightly without causing twisting or warpage.

Specifications:

| Minimum pattern width (mm) | 0.1 (4 mil) | |

| Minimum milling width (mm) | 0.1 (4 mil) | |

| Working area (X/Y/Z) (mm) | 229 x 300 x 45 (9.0″ x 11.8″ x 1.8″) | |

| Table size (X/Y) (mm) | 296 x 370 (11.6″ x 14.5″) | |

| Control axis | X, Y, Z | |

| Control motor | Stepper Motor | |

| Resolution (µm) | 0.156 (0.00614 mil) | |

| Maximum Travel Speed (mm/sec.) | 55 (2.17″) | |

| Spindle speed min-1 (rpm) Spindle motor | 5,000 – 100,000 HF Spindle | |

| Drilling (mm) | 0.2 – 3.175 (8 – 125 mil) | |

| Maximum drilling cycle (cycles/min.) | 55 | |

| Maximum thickness of processed material (mm) | 10 (0.4″) | |

| Tool change | Automatic / 10 | |

| Milling method | Absolute | No |

| Incremental | Yes | |

| Compressed air (Mpa) | 0.6 | |

| Power consumption | 100 – 240 V, 50-60 Hz, 200VA | |

| Machine dimensions W x D x H (mm) | 435 x 575 x 430 (17.2″ x 23″ x 17″) With cabinet: 500 x 580 x 450 (19.7″ x 23″ x 18″) | |

| Machine weight (kg) | Approx. 34 (76 lbs) With cabinet: Approx. 44 (99 lbs) | |

| Interface | One USB or one RS-232C port | |

| Standard equipment | Fiducial positioning camera 30x (USB) 10 Pieces Auto Tool Change Software: EASY CAD, Conversion & CAM | |

| Options and accessories | Cabinet (requires assembly) Vacuum table Ring-setter / Precision ring-setter (manual) Drilling ring Microscope 100x Software: Vacuum cleaner | |

Accessories

-

Drill Resolution:

-

Drilling Speed:

-

Workspace Size:

PCB Prototyping Mits Eleven Lab 60

-

Workspace Size:

-

Drill Resolution:

-

Drilling Speed:

PCB Prototyping Mits Auto Lab W

-

Workspace Size:

-

Drill Resolution:

-

Drilling Speed:

PCB Prototyping Mits Auto Lab 100

-

Workspace Size:

-

Drill Resolution:

-

Drilling Speed:

PCB Prototyping Mits Eleven Lab+P

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

MITS PCB Prototyping Machine Lineup FP-21T / 21THP

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

PCB Prototyping Machine AutoLab

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

PCB Prototyping Machine ElevenLab

-

Drill Resolution:

-

Drilling Speed:

-

Workspace Size:

PCB Prototyping Mits Eleven Lab 60

-

Workspace Size:

-

Drill Resolution:

-

Drilling Speed:

PCB Prototyping Mits Auto Lab W

-

Workspace Size:

-

Drill Resolution:

-

Drilling Speed:

PCB Prototyping Mits Eleven Lab+P

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

MITS PCB Prototyping Machine Lineup FP-21T / 21THP

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

PCB Prototyping Machine AutoLab

-

Workspace Size:

-

Drilling Speed:

-

Drill Resolution:

PCB Prototyping Machine ElevenLab

Please login to write review!