Keithley 2520 Pulsed Laser Diode Test System

Hotline: +84 906 988 447

Head Office: Ho Chi Minh City

- Tel: +84 2839 778 269 / 3601 6797

- Email: sales@lidinco.com

- Add: 487 Cong Hoa Street, Tan Binh Ward, Ho Chi Minh City, Vietnam

Office: Bac Ninh City

- Tel: +84 222 730 0180

- Email: bn@lidinco.com

- Add: 184 Binh Than Street, Vo Cuong Ward, Bac Ninh, Vietnam

-

Technical Counseling

100% Free

Technical Counseling

100% Free

-

Free Shipping

For 3.000.000vnd Order

Free Shipping

For 3.000.000vnd Order

Data is being updated

Description

Keithley instrumentation makes it easy to build a LIV (light-current-voltage) system to test laser diode modules cost-effectively.

- 2520 Pulse Laser Diode Test System: Synchronizing test system providing sourcing and measurement capability for pulsed and continuous LIV test.

- TEC SourceMeter SMUs, 2510 and 2510-AT: Ensure tight temperature control for laser diode modules by controlling its thermo-electric cooler.

The Model 2520 Pulsed Laser Diode Test System is an integrated, synchronized system for testing laser diodes early in the manufacturing process, when proper temperature control cannot be easily achieved. The Model 2520 provides all sourcing and measurement capabilities needed for pulsed and continuous LIV (light-current-voltage) testing of laser diodes in one compact, half-rack instrument. The tight synchronization of source and measure capabilities ensures high measurement accuracy, even when testing with pulse widths as short as 500ns.

LIV Test Capability

The Model 2520 can perform pulsed LIV testing up to 5A and continuous LIV testing up to 1A. Its pulsed testing capability makes it suitable for testing a broad range of laser diodes, including the pump laser designs for Raman amplifiers. The instrument’s ability to perform both DC and pulsed LIV sweeps on the same device simplifies analyzing the impact of thermal transients on the LIV characteristics of the laser diode.

Maximize Throughput and Eliminate Production Bottlenecks

By working in cooperation with leading laser diode manufacturers, Keithley designed the Model 2520 specifically to enhance chip- and bar-level test stand yield and throughput. Its integrated design, ease of use, high speed, and high accuracy provides a complete solution to help laser diode manufacturers meet their production schedules. Producers of laser diodes face constant pressure to increase test throughput and optimize return on investment for their capital equipment used in production testing. Until recently, these producers were forced to use relatively slow and cumbersome test stands for testing laser diodes at the chip and bar level, which often led to production bottlenecks.

Remote Electrical Test Head included

Higher Resolution for Higher Yields

To achieve the required signal-to-noise ratio, traditional chip- and bar-level LIV testing solutions have required the use of boxcar averagers or test system control software modifications to allow averaging several pulsed measurements. The resolution of these measurements is critical for the “kink” test and threshold current calculations. With earlier test system designs, particularly when performing the kink test, low resolution and poor linearity of the analog digitizer made it extremely difficult to discriminate between noise in the measurement and an actual device kink. The Model 2520’s unique DSP-based meas urement approach automatically identifies the settled region of the pulsed waveforms measured. This means the Model 2520 stores only that portion of the pulse that is “flat” and contains meaning ful data. All measurements made in the flat portion of the pulse are averaged to improve the Signal-to-Noise ratio still further. If greater resolution is required, the Model 2520 can be programmed to perform several pulse and measure cycles at the same pulse amplitude. By making it possible to conduct more thorough testing at the bar or chip level, the Model 2520 also eliminates the wasted time and costs associated with assembling then scrapping modules with non-compliant diodes.

Simple, One-Box Test Solution

The Model 2520 offers three channels of source and measurement circuitry. All three channels are controlled by a single digital signal processor (DSP), which ensures tight synchronization of the sourcing and measuring functions. The laser diode drive channel provides a current source coupled with voltage measurement capability. Each of the two photodetector channels supplies an adjustable voltage bias and voltage compliance, in addition to current measurement capability. These three channels provide all the source and measure capabilities needed for full LIV characterization of laser diodes prior to integration into temperature controlled modules. By eliminating the need for GPIB commands to perform test sweeps with multiple separate instruments, the Model 2520’s integrated sourcing and measurement allows a significant improvement in throughput.

Remote Test Head Maximizes Signal-to-Noise Ratio

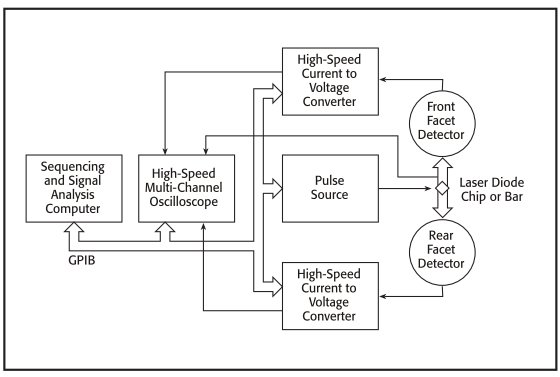

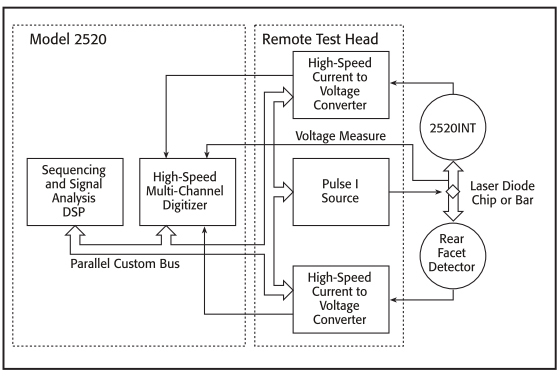

The mainframe and remote test head architecture of the Model 2520 is designed to enhance pulsed measurement accuracy, even at the sub-microsecond level. The remote test head ensures the measurement circuitry is located near the DUT, mounted on the fixture, minimizing cable effects. As the schematic in Figure 1 shows, traditional semi-custom systems typically employed in the past require significant integration. The architecture of the Model 2520 (Figure 2) offers a far more compact and ready-to-use solution.

High Speed Pulse and Measure to Minimize Thermal Effects

The Model 2520 can accurately source and measure pulses as short as 500 nanoseconds to minimize unwanted thermal effects during LIV testing. Users can program the pulse width from 500ns to 5ms and pulse off time from 20µs to 500ms. There is a software duty cycle limit of 4% for currents higher than 1A. To ensure greater accuracy, the instrument provides pulse width programming resolution levels of 10µs (off time) and 100ns (on time).

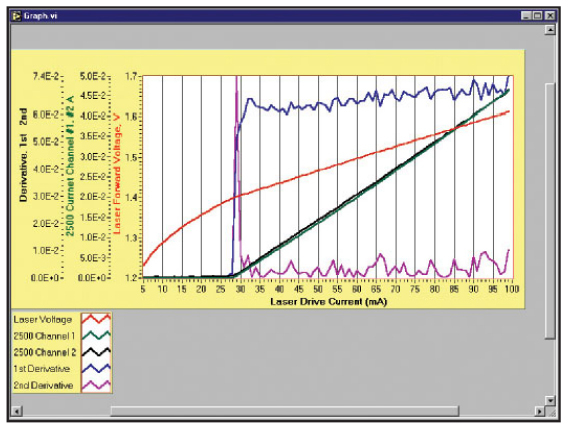

Prior to the introduction of the Model 2520, test instrument limitations often placed barriers on test per formance. However, with the Model 2520, the limiting factor is not the test instrument, but the physics of the connections to the device. Keithley’s optoelectronics applications engineers have addressed these issues by studying and documenting the optimum cable configuration to en hance measurement accuracy with extremely fast pulses. Figure 3 illustrates the results of a typical pulse LIV sweep test with the Model 2520. In this test, a 100-point pulsed LIV sweep using a 1µs pulse width, at 1% duty cycle, was completed in just 110ms (including data transfer time), several orders of magnitude faster than existing, semi-custom test systems.

Figure 1. This schematic reflects the current testing practices of major laser diode manufacturers. Note that the use of discrete test components increases the integration and programming effort, while severely limiting the flexibility of the test system.

Figure 1. This schematic reflects the current testing practices of major laser diode manufacturers. Note that the use of discrete test components increases the integration and programming effort, while severely limiting the flexibility of the test system.

Figure 2. The Model 2520 integrates synchronization, source, and measure capabilities in a single half-rack instrument (with remote test head) to provide maximum flexibility and test throughput.

Figure 2. The Model 2520 integrates synchronization, source, and measure capabilities in a single half-rack instrument (with remote test head) to provide maximum flexibility and test throughput.

ESD Protection

A laser diode’s material make-up, design, and small size make it extremely sensitive to temperature increases and electrostatic discharges (ESDs). To prevent damage, prior to the start of the test and after test completion, the Model 2520 shorts the DUT to prevent transients from destroying the device. The instrument’s 500 nano second pulse and measure test cycle minimizes device heating during test, especially when a short duty cycle is used.

Figure 3. This plot illustrates the Model 2520’s pulsed LIV sweep capability. The sweep was programmed from 0 to 100mA in 1mA steps. Pulse width was programmed at 1µs at 1% duty cycle, providing for a complete sweep in just 10ms (excluding data transfer time).

Test Sequencing and Optimization

Up to five user-definable test setups can be stored in the Model 2520 for easy recall. The Model 2520’s built-in Buffer Memory and Trigger Link interface can reduce or even eliminate time- consuming GPIB traffic during a test sequence. The Buffer Memory can store up to 1000 points of meas urement data during the test sweep. The Trigger Link combines six independent software selectable trigger lines on a single connector for simple, direct control over all instruments in a system. This interface allows the Model 2520 to operate autonomously following an input trigger. The Model 2520 can be programmed to output a trigger to a compatible OSA or wavelength meter several nano seconds prior to outputting a programmed drive current value to initiate spectral measurements.

Figure 4. Model 2520 Remote Test Head

Accessories and Options

The Model 2520 comes with all the interconnecting cables required for the main instrument and the remote test head. Production test practices vary widely (automated vs. semi-automated vs. manual), so the cable assemblies from the remote test head to the DUT can vary significantly. To accommodate these differing requirements, Keithley has developed the Model 2520 RTH to DUT Cable Config ura tion Guide to help customers determine the proper cable assemblies to use to connect the remote test head (RTH) to the DUT.

Interface Options

The Model 2520 provides standard IEEE-488 and RS-232 interfaces to speed and simplify system integration and control. A built-in digital I/O interface can be used to simplify external handler control and binning operations.

Additional LIV Test Solutions

For production testing laser diodes after they have been packaged in temperature controlled modules, Keithley offers the Laser Diode LIV Test System with increased 28-bit core measurement resolution, allowing for more detailed characterization. This flexible system combines all the DC measurement capabilities required to test these modules with tight temperature control over the DUT in a modular instrument package. Configured from proven Keithley instrumentation, the basic configuration can be easily modified to add new measurement functions as new testing needs evolve.

Applications:

- Production testing of:

- Telecommunication laser diodes

- Optical storage read/write head laser diodes

- Vertical Cavity Surface-Emitting Lasers (VCSELs)

- Thermal impedance

- Junction temperature response

| GENERAL SPECIFICATIONS | |

| DC FLOATING VOLTAGE | User may float common ground up to ±10VDC from chassis ground |

| COMMON MODE ISOLATION | >10 9 Ω |

| OVERRANGE | 105% of range on all measurements and voltage compliance |

| SOURCE OUTPUT MODES | Fixed DC Level Fixed Pulse Level DC Sweep (linear, log, and list) Pulse Sweep (linear, log, and list) Continuous Pulse (continuous – low jitter) |

| PROGRAMMABILITY | IEEE-488 (SCPI-1995.0), RS-232, 5 user-definable power-up states plus factory default and *RST |

| DIGITAL INTERFACE | |

| Safety Interlock | External mechanical contact connector and removable key switch |

| Aux. Supply | +5V @ 300mA supply |

| Digital I/O | 2 trigger input, 4 TTL/Relay Drive outputs (33V @ 500mA max., diode clamped) |

| Trigger Link | 6 programmable trigger input/outputs |

| Pulse Trigger Out BNC | +5V, 50Ω output impedance, output trigger corresponding to current source pulse; pulse to trigger delay <100ns |

| MAINS INPUT | 100V to 240V rms, 50–60Hz, 140VA |

| EMC | Conforms to European Union Directive 89/336/EEC (EN61326-1) |

| SAFETY | Conforms to European Union Directive 73/23/EEC (EN61010-1) CAT 1 |

| VIBRATION | MIL-PRF-28800F Class 3, Random |

| WARM-UP | 1 hour to rated accuracy |

| DIMENSIONS, WEIGHT | |

| Main Chassis, bench configuration (with handle & feet) | 105mm high × 238mm wide × 416mm deep (4 1 / 8 in. × 9 3 / 8 in. × 16 3 / 8 in.). 2.67kg (5.90 lbs). |

| Remote Test Head | 95mm high × 178mm deep (with interlock key installed) × 216mm wide (3½ in. × 7 in. × 8½ in.). 1.23kg (2.70 lbs). |

| ENVIRONMENT | |

| Operating | 0°–50°C, 70% R.H. up to 35°C. Derate 3% R.H./°C, 35°–50°C |

| Storage | –25° to 65°C |

| LASER DIODE PULSE OR DC CURRENT SOURCE SPECIFICATIONS | |||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

| TEMPERATURE COEFFICIENT (0°–18°C & 28°–50°C) | ±(0.15 × accuracy specification)/°C | ||||||||||||||||||||||||||||||||

| PULSE ON TIME | 500ns to 5ms, 100ns programming resolution | ||||||||||||||||||||||||||||||||

| PULSE OFF TIME | 20µs to 500ms, 10µs programming resolution | ||||||||||||||||||||||||||||||||

| PULSE DUTY CYCLE | 0 to 99.6% for =1.0A; 0 to 4% for >1.0A | ||||||||||||||||||||||||||||||||

| VOLTAGE COMPLIANCE | 3V to 10V, 10mV programming resolution | ||||||||||||||||||||||||||||||||

| POLARITY | 1 quadrant source, polarity reversal available through internal relay inversion | ||||||||||||||||||||||||||||||||

| OUTPUT OFF | <200mΩ short across laser diode; measured at Remote Test Head connector | ||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

| LASER DIODE VOLTAGE MEASURE SPECIFICATIONS | |||

| Range | Minimum Resolution | Accuracy ±(%rdg. + volts) | RMS Noise (typical) |

| 5.00 V | 0.33 mV | 0.3% + 6.5 mV | 60 µV |

| 10.00 V | 0.66 mV | 0.3% + 8 mV | 120 µV |

| TEMPERATURE COEFFICIENT (0°–18°C & 28°–50°C) | ±(0.15 × accuracy specification)/°C | ||

| MAX. LEAD RESOLUTION | 100Ω for rated accuracy | ||

| INPUT IMPEDANCE | 2MΩ differential, 1MΩ from each input to common. Input bias current ±7.5µA max | ||

| PHOTODIODE VOLTAGE BIAS SOURCE SPECIFICATIONS (each channel) | |||

| RANGE | 0 to ±20VDC | ||

| PROGRAMMING RESOLUTION | 10mV | ||

| ACCURACY | ±(1% + 50mV) | ||

| CURRENT | 160mA max. with V-Bias shorted to I-Measure | ||

| RMS NOISE (1kHz to 5MHz) | 1mV typical | ||

| PHOTODIODE CURRENT MEASURE SPECIFICATIONS (each channel) | ||||

| Range | Minimum Resolution | DC Input Impedance | Accuracy ±(%rdg. + current) | RMS Noise (typical) |

| 10.00 mA | 0.7 µA | < 10 Ω | 0.3% + 20 µA | 90 nA |

| 20.00 mA | 1.4 µA | < 6 Ω | 0.3% + 65 µA | 180 nA |

| 50.00mA | 3.4 µA | < 3 Ω | 0.3% + 90 µA | 420 nA |

| 100.00 mA | 6.8 µA | <2.5 Ω | 0.3% + 175 µA | 840 nA |

| TEMPERATURE COEFFICIENT (0°–18°C & 28°–50°C) | ±(0.15 × accuracy specification)/°C. | |||

| INPUT PROTECTION | The input is protected against shorting to the associated channel’s internal bias supply. The input is protected for shorts to external supplies up to 20V for up to 1 second with no damage, although calibration may be affected | |||

| SYSTEM SPEEDS | ||

| READING RATES (ms) | ||

| Number of Source Points | To Memory | To GPIB |

| 1 | 5.3 | 6.8 |

| 10 | 9.5 | 18 |

| 100 | 48 | 120 |

| 1000 | 431 | 1170 |

- Keithley Shielded GPIB Cable,1M (3.2FT)

- Keithley Shielded GPIB Cable,2M (6.5FT)

- Tektronix TekSelect Shielded GPIB Cable,1M (3.2FT) -- FINAL SALE NR / NC

- Tektronix TekSelect Shielded GPIB Cable,2M (6.5FT) -- FINAL SALE NR / N

Accessories

- Keithley Shielded GPIB Cable,1M (3.2FT)

- Keithley Shielded GPIB Cable,2M (6.5FT)

- Tektronix TekSelect Shielded GPIB Cable,1M (3.2FT) -- FINAL SALE NR / NC

- Tektronix TekSelect Shielded GPIB Cable,2M (6.5FT) -- FINAL SALE NR / N

-

Voltage Source:

-

Current Source:

-

Voltage Resolution:

-

Current Resolution:

Semiconductor Device Parameter Analyzer Keysight B1500A

-

Voltage Source:

-

Current Source:

-

Current Resolution:

-

Voltage Resolution:

Keithley 2520/KIT1 Pulsed Laser Diode Measurement Kit

-

Voltage Source:

-

Current Source:

-

Current Resolution:

Parametric Analyzers Keithley 4200-SCS

-

Voltage Source:

-

Current Source:

-

Voltage Resolution:

-

Current Resolution:

High Power SourceMeter Keithley 2657A (1fA / 100nV)

Please login to write review!